In December 2022, to increase production capacity, FERMI’s Hubei factory ordered another material blanking machine, a slitting machine, a pressing machine, and a fully automatic punching machine. These machine and equipment are mainly used to produce abrasive belts, facilitating addition of another production line.

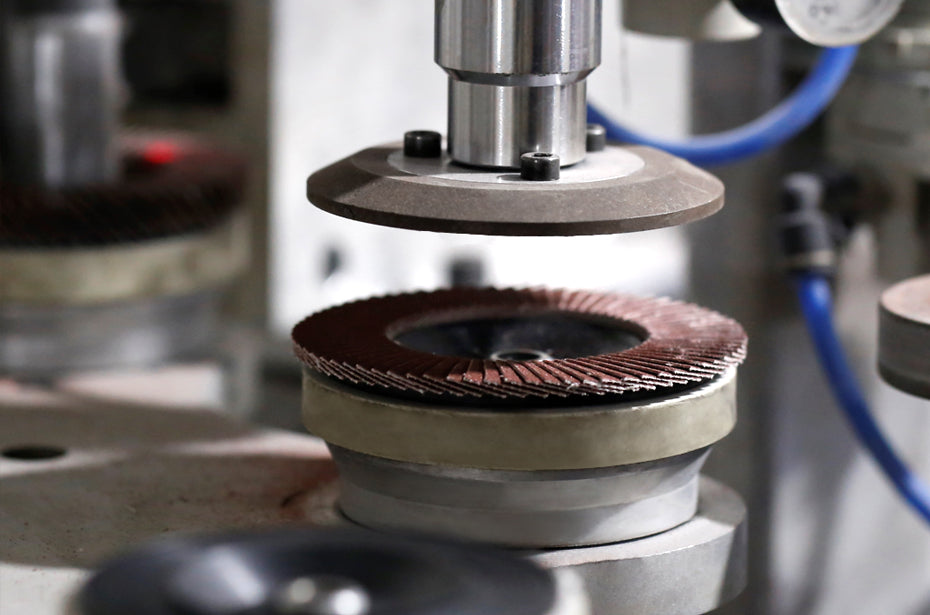

The fully automatic punching machine is specifically used for punching hard cloth-coated sanding discs. At present, FERMI has a variety of cloth-covering processes for quick change discs, which greatly improves the flatness of the sanding discs and basically meets the needs of customers in the market.

Our high demands for sanding discs quality have won trust from our customers. Up to now, FERMI has owned more than 100 sets of large and small equipment, fully covering production of abrasive sanding belts, flap wheels, flap discs, mounted flap wheels, straight (tapered) cartridge rolls, spiral bands, sanding discs, hand pads, etc. Each product can be processed by multiple production lines simultaneously, which greatly improves efficiency and shortens order delivery time.

In November 2022, FERMI's Hubei factory completed the second-round upgrade, expanded the production workshop and warehouse area. Up to now, the total construction area of FERMI's Wuxi factory and Hubei factory has reached 7,000 square meters (76,000 sq ft2). The factory owns considerable production and storage capacity. Fermi continues to take firm and steady steps to provide customers with better prices, better products, and services.